COVID-19 Online Screening Tool: Answer on your smartphones or computers within 24 hours prior to your visit to The Medical City.

How 3D Printing and Personalized Medicine Transformed a Patient's Life

By The Medical City (TMC), Ortigas | May 09, 2025

The Medical City successfully performed a personalized 3D-printed cranial reconstruction to restore a patient’s skull after traumatic brain injury, showcasing innovation in precision surgery.

In September 2023, a patient suffered a workplace accident that led to a life-altering injury and a long journey toward recovery. Left with a traumatic brain injury, he underwent a 3D-printed cranial reconstruction at The Medical City in January 2025 —a surgical innovation that helped restore the shape of his skull and gave him a renewed sense of normalcy.

A Personal Fit for a Better Recovery

The patient was electrocuted while changing a lightbulb, resulting in severe brain trauma. To relieve pressure caused by internal bleeding, doctors performed an emergency craniectomy — a surgical procedure where a portion of the skull is temporarily removed to allow a swelling brain to expand without being compressed.

While the craniectomy saved his life, it left a section of his skull missing, creating both cosmetic and protective challenges. Years later, the patient returned for cranial reconstruction to restore the skull's original shape and function.

In the past, doctors used materials like metal plates or bone grafts to repair such defects, but these options sometimes resulted in complications such as infection, heat sensitivity, or discomfort.

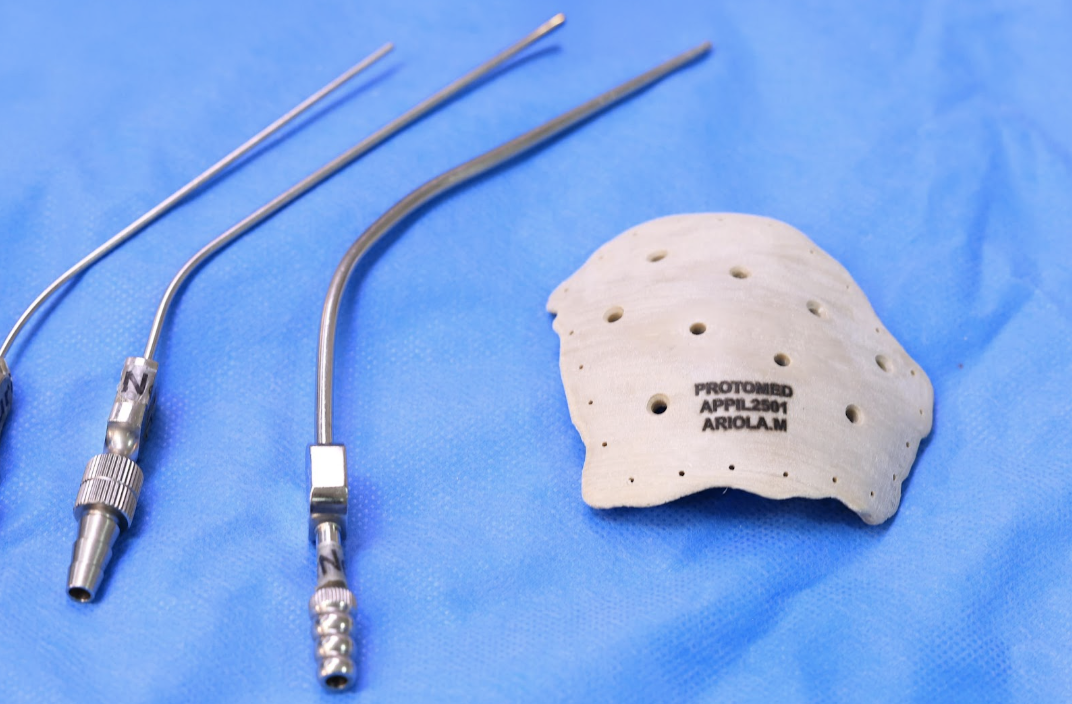

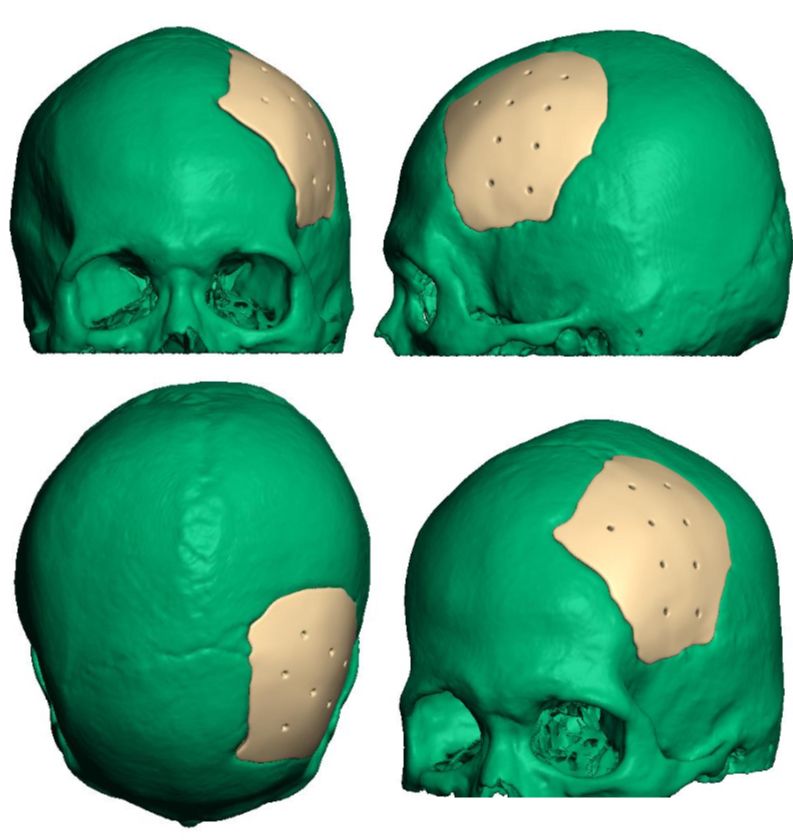

3D-printed PEEK cranial implant, custom-fit for patient-specific reconstruction.

At TMC, the patient was given a 3D-printed PEEK cranial implant. It is a custom-made medical device created using advanced imaging and 3D-printing technology. PEEK stands for polyether ether ketone, a biocompatible, durable plastic that mimics the properties of human bone. It is lightweight, strong, and does not conduct heat or cold, which makes it more comfortable than traditional metal implants.

Using detailed CT scans of his head, a team of doctors and biomedical engineers designed an implant shaped precisely to match the missing portion of the patient’s skull. This personalized approach allowed for a better fit, minimized surgical risks, and improved healing.

3D Skull design implant for the patient.

The implant used in this case was made and generously donated by ProtoMed Singapore, a company dedicated to producing patient-specific implants for cranial and maxillofacial applications using 3D printing technology. William Chia and Aravinda Jayawardhana, both Sales and Operations Directors, and Cindy Tan, Finance Director, represented ProtoMed in supporting this milestone case.

A Smooth Recovery and a Fresh Start

Dr. Jerold Justo and medical team performing 3D-printed cranial reconstruction.

The surgery, led by Dr. Jerold Justo, along with Dr. John Dy, Dr. Jec Eustaquio, and Dr. Michelle Luciano, was a success. By practicing personalized medicine and looking after the patients' unique needs, the surgical team was able to significantly reduce operative time, lower risks associated with longer procedures, and promote faster recovery. He recovered well with no complications and was soon able to return to his home province of Aklan. Today, he has resumed his normal activities and is doing well.

“This technology has made a huge difference in how we do surgeries, reducing operative times and improving the patient’s recovery and ultimately, their quality of life,” said Dr. Justo. “It’s exciting to see how we can use innovation to improve and personalize patient care.”

The Future of 3D-Printed Surgery

Before (upper left) and after (lower left and right) photos showing the successful outcome of the procedure.

Looking ahead, Dr. Justo shared that this technology holds promise for broader applications, including patient education, bone reconstruction in orthopedic and ENT (ear, nose, and throat) surgeries, and even simulations in complex cases.

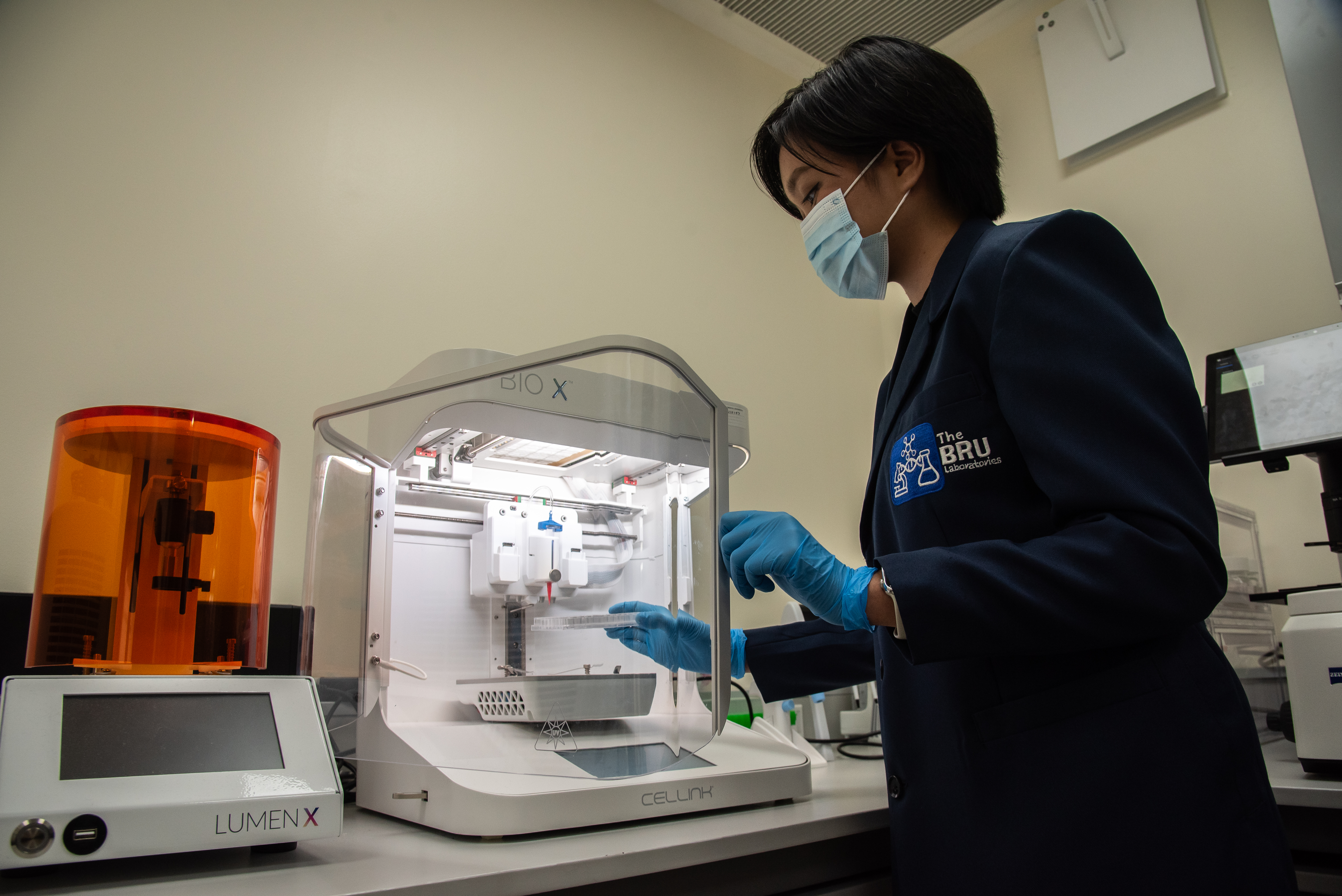

This project was made possible by TMC’s Clinical and Translational Research Institute, led by Dr. Raul V. Destura and Dr. Roland G. Remenyi, head of CTRI’s Biomedical Research Unit. The collaboration with ProtoMed Singapore was facilitated by Eleanor Olegario of Lithos Manufacturing, who learned about TMC’s ongoing research at the Hyper Interdisciplinary Conference organized by the Philippine subsidiary of the Leave a Nest group. Olegario's association with Protomed started in May 2023 with a medical and building mission hosted by Lithos Manufacturing in a remote community in Mangatarem, Pangasinan, with the Singaporeans as volunteers.

By adopting technologies such as 3D printing for patient-specific implants, TMC strengthens its leadership in personalized, precision-based treatment for better patient outcomes and quality of life.

For inquiries about our services or to book a consultation with our doctor, send us a message at m.me/TheMedicalCity.

Related News SEE ALL NEWS

Health

The Gift of a Second Life

Health #MyTMCExperience Press Room

She Thought It Was Just Heartburn—It Was Actually a Heart Attack

Health Research

Tissue Engineering for a Future without Organ Shortages

Health Press Room

Chikiting Ligtas: Addressing the Gap in Immunization Coverage

Health Corporate

Notice to the Shareholders of Professional Services Inc. (PSI)

Health Corporate

Notice to the Shareholders of Professional Services Inc. (PSI)

Health Corporate

Notice to the Shareholders of Professional Services, Inc. (PSI)

Health #MyTMCExperience

Friendship goals: See the world better, TOGETHER

Health #MyTMCExperience

#MyTMCexperience: Rod Cruz

Health TeleHealth COVID-19

Back to Health, Back to the City

Health Corporate Advisories

Notice of Annual Meeting of Stockholders

Health Corporate

Pedalling through Safety

Health

Diabetes and COVID-19

Health

FAQs on Patient Portal

Health

2021 Holy Week Schedule

Health

How serious is fatty liver?

Health Desk of the President

Oxford Business Group: The Report 2021 - Addressing the Gaps

Health TeleHealth

Need an advice from an Orthopedic Specialist?

Health

Welcome 2021 in good health

Health

Change Your 2020 Vision

Health COVID-19

Convalescent Plasma Donation for COVID–19 Survivors

Health

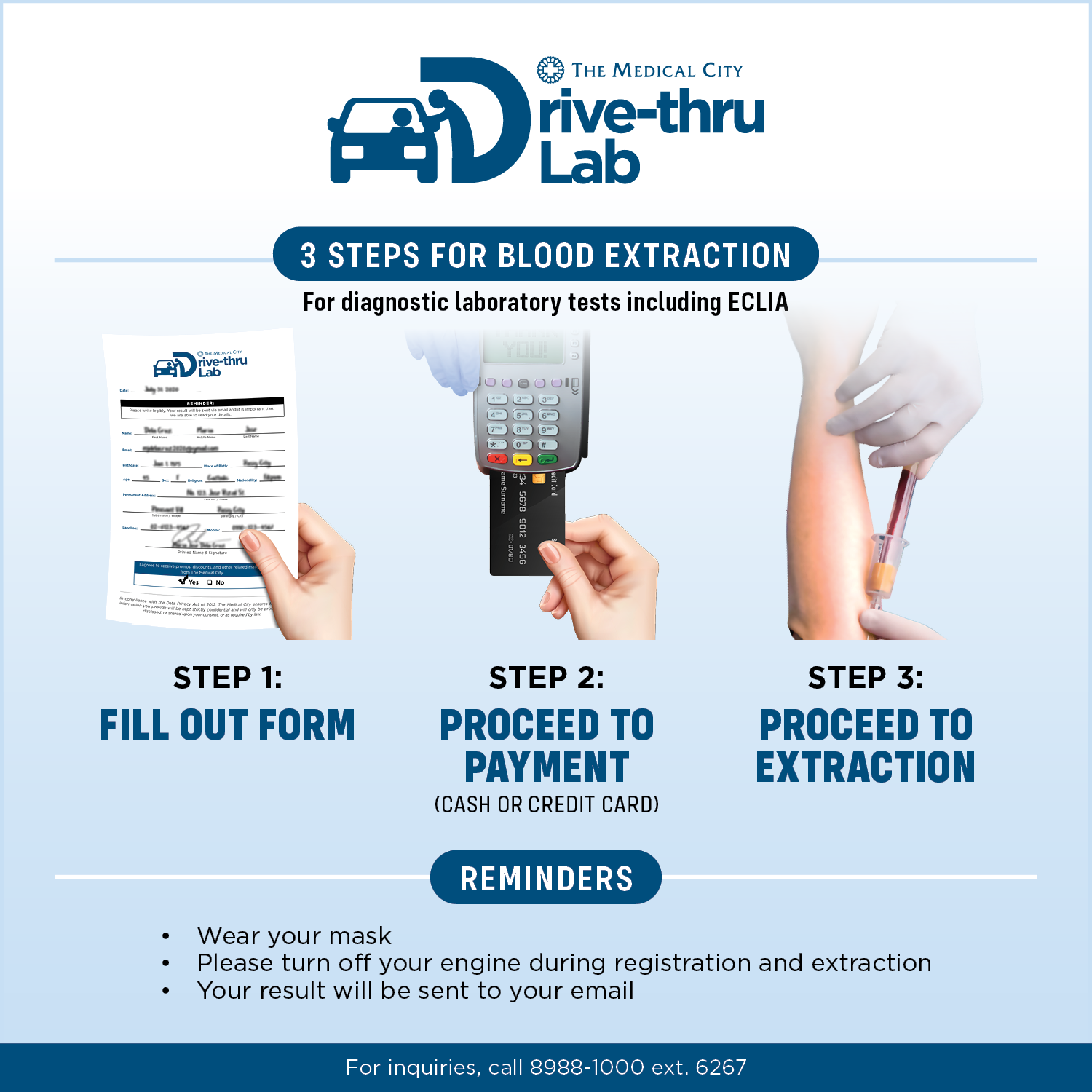

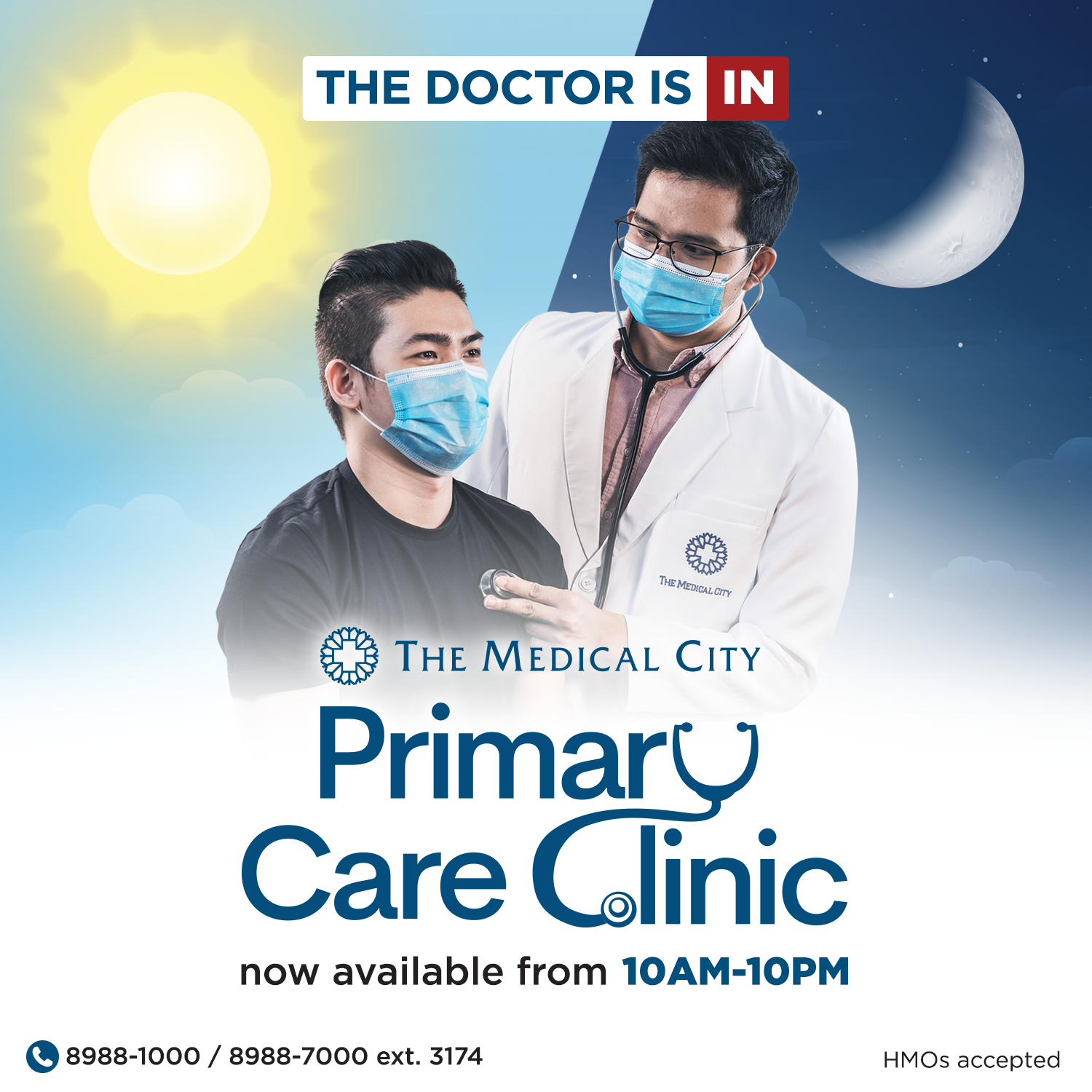

FAQs on TMC Drive-thru Lab

Health

Be in and out in 90 minutes

Health

Schooling in the New Normal

Health

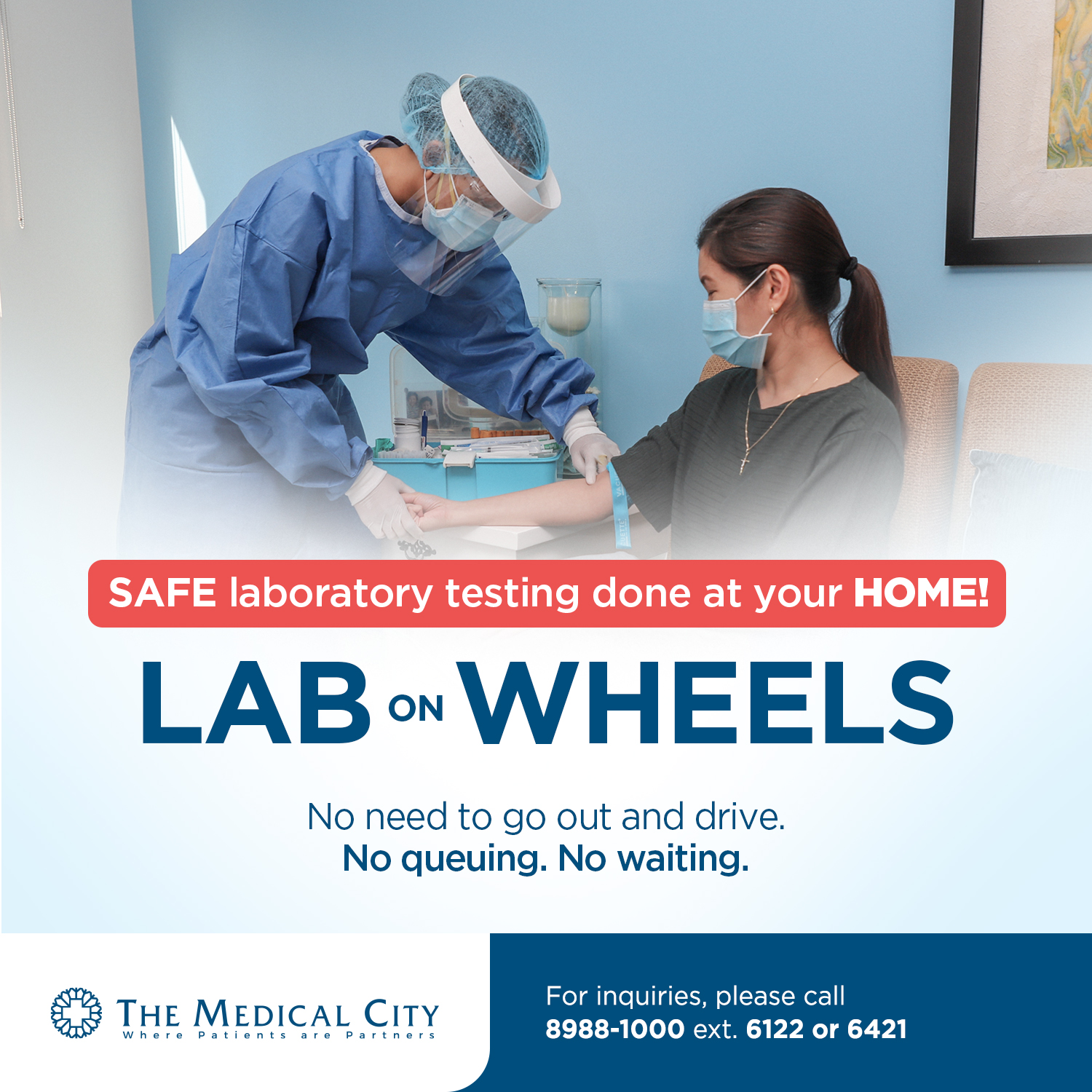

TMC Lab on Wheels

Health

Autism

Health

Eye Health in Computer Work

Health

Speech Delay

Copyright © 2020 The Medical City. All rights reserved.